866-685-4443 | Get in Touch Online ...

What "Self-Regulating" Really Means

(Part of our collection of articles on Everything You Need to Know about Heating Cable)

One product of ours that generates more questions than most is self-regulating heat cable. The word "self-regulating" seems to say that the cable will come to a certain, set temperature, and stay there for as long as it's powered on, which would usefully eliminate the need for any thermostat or other means of temperature control. Unfortunately, the reality of self-regulating cable is more complicated. There are some cases where a temperature controller isn't needed, but in most situations, it's important to incorporate a control into the system to avoid wasting electricity and money, and to avoid inevitable mishaps.

Not really "self-regulating"

The first important thing to know is that "self-regulating" is actually a somewhat misleading term, coined many years ago by the original creator of the product. A more accurate way to describe it is "self-limiting." Its main advantage over standard heating cable is not that it maintains a specific operating temperature, but rather that it cannot get hot enough to overheat and cause damage to itself. That is to say, the cable is built in such a way that, as it gets hotter, it allows progressively less electricity to flow, until at some point – somewhere below a temperature that would cause damage to the cable – electricity stops flowing entirely and the cable stops heating up.

What exactly does it do?

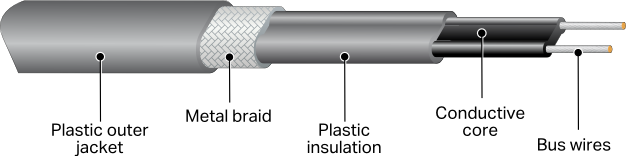

Heating cable has four to five layers made of different materials:

Most of these layers are fairly self-explanatory. The outer jacket (not present on all cables) serves to shield the cable against moisture and mechanical damage, and the metal braiding electrically grounds the cable. The inner plastic insulation is actually the main layer of electrical insulation between the live-current heater and the outside, and the bus wires are the means of connecting the heater to the power source.

Most of these layers are fairly self-explanatory. The outer jacket (not present on all cables) serves to shield the cable against moisture and mechanical damage, and the metal braiding electrically grounds the cable. The inner plastic insulation is actually the main layer of electrical insulation between the live-current heater and the outside, and the bus wires are the means of connecting the heater to the power source.

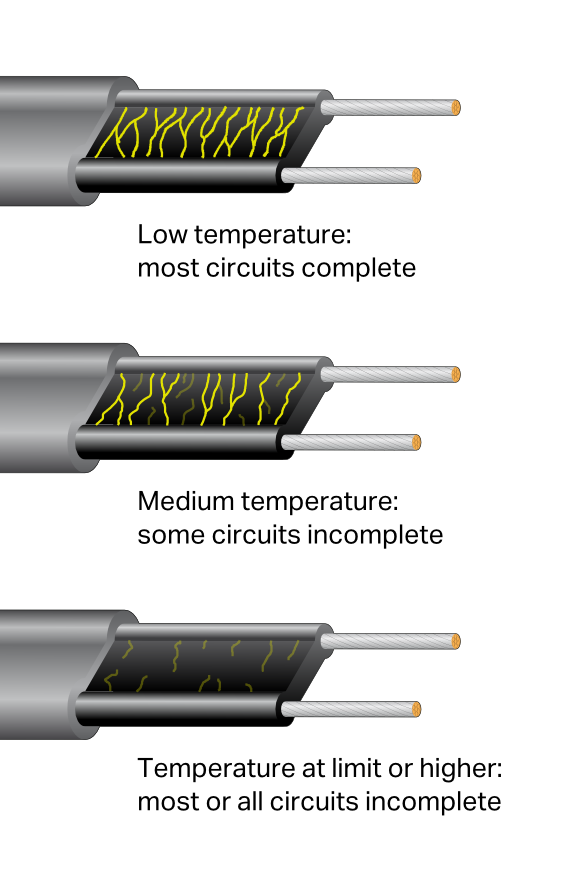

The conductive core is where the real action of self-limiting occurs. This core is made of a special plastic that is electrically conductive at low temperatures and insulating at high temperatures. This behavior makes it what's called a PTC element, for "positive temperature coefficient" – meaning that as the temperature goes up, so does the resistance. (The "coefficient" in this case is the k in the equation R = kT, where R is the resistance, T is the temperature, and k is a constant ratio relating the two. This equation is an oversimplification of the actual operation, but it illustrates the general idea.) The heat comes from the plastic's resistance: as electricity flows through the resistive plastic, some of it is absorbed by the plastic and turned into heat, in much the same way electricity is absorbed by the tungsten coil of an incandescent light bulb and turned into light.

How does it do that?

It's a pretty clever trick of engineering and the material used for the core. First, note that the positive and negative bus wires don't actually touch one another at any point. That means all the electricity for completing the circuit is flowing through the conductive core itself. Within this core, millions of microscopic electrical pathways are flowing from one bus wire to the other through the matrix of the core, and each of these circuits has a small amount of resistance, turning it into a classic resistive heating element. The core gets hotter and begins to warm up your work load – and, like most materials do, it physically expands in the heat. However, it expands somewhat irregularly at the microscopic level, opening up gaps in the matrix, and these gaps break apart some of the tiny electrical pathways. The hotter the core gets, the more it expands, the more gaps open up in the matrix, and the fewer circuits are completed. Finally, at some temperature, the matrix is too full of gaps for any current to be allowed through, and the cable stops generating any heat.

So why do I need a control?

Energy savings

The most important reason is energy. Let's say you're using self-limiting cable to stop a water pipe from freezing. Installed properly, the cable will certainly keep the water from freezing – but it won't stop there. It will keep pumping heat into the pipe and the water; meanwhile, most of that heat will be taken right back out of the system by the sharp temperature difference between the pipe and the outside air (unless you have extremely thick insulation), as well as the water flowing through the pipe. And so the cable won't reach its shut-off temperature. In fact, it's likely to stay at a fairly cool temperature – which is right where it has the highest energy draw. The situation is even worse if the cable is in a gutter or on a roof, exposed with no insulation. If you're running on grid power, you'll see some shockingly high electric bills; if you're running from a battery (say, with a solar array), you may find your battery dead and your pipes frozen in the morning.

Forgetfulness

Another reason is human forgetfulness. When it gets warm, heating cables mostly get switched off or unplugged (for the season or just for the day), to save energy. We'd all like to think we'll remember to switch the cable back on when it gets cold again, but experience has taught us that a human is probably the least reliable switching mechanism there is. And it only takes forgetting once to end up with frozen pipes or ice dams, at which point you're usually past the point where heating cable can help you.

Precision

One last reason is precision. Self-limiting cable is actually used fairly often in industrial applications that need to maintain a temperature within a certain range. In those cases, it's specified exactly because of its inherent high-limit feature, which removes concerns about the cable overheating and damaging itself and the work load. But it would be a mistake to think "self-regulating" cable can regulate a system to precisely the temperature listed on its spec sheet, even to within a broad deadband. The precise temperature reached depends on many complex variables, and regulating imprecisely on the input side just through choice of cable will never achieve the accuracy that even a basic thermostat can offer by measuring the actual heat produced.

All in all, the one-time cost of a temperature controller will almost certainly outweigh the costs of high energy bills, downtime, pipe or gutter replacement, and any other costs that might spring up with uncontrolled heating cable. If you need help choosing the right kind of temperature controller, or if you'd still like to learn more, you can always get in touch with us: chat with an engineer at (866) 685-4443, email us at info@oemheaters.com, or send in one of our contact forms. We're here to help with all your questions.