866-685-4443 | Get in Touch Online ...

How to Specify an Air Process Heater

Forced-air process heating is one of the more technically complex industrial electric heating applications. However, like most heating applications, it largely boils down to finding the right numbers for two values: the wattage and the watt density.

Wattage

For most air heating processes, it's fairly simple to find the wattage required. If your incoming air is at any temperature lower than 120°F (49°C), you can use this simple formula:

kW = Rflow • ΔT3,000 • 1.2

Where

- kW is the required heater power, in kilowatts;

- Rflow is the rate of air flow in SCFM (standard cubic feet per minute – not actual CFM);

- ΔT is the rise in temperature in °F; and

- 1.2 is included as a suggested 20% safety factor.

This is a simplification of a more complicated formula; applications with incoming air at temperatures above 120°F or pressure much in excess of 1 atmosphere (14.7 psi) will need to use the more complicated formula, which is shown here:

kW = Rflow • D • 60 min • Cp • ΔT3,412 Btu/kW • 1.2

Where

- kW is the required heater power, in kilowatts;

- D is the density of the incoming air or gas, in lb/ft³;

- Rflow is the rate of air flow in ACFM (actual cubic feet per minute);

- Cp is the specific heat of the air or gas, in Btu/lb/°F;

- ΔT is the rise in temperature in °F; and

- 1.2 is included as a suggested 20% safety factor.

Watt density

Your main consideration with watt density is to make sure that you're getting a heater that can handle the wattage you need to put into it. For this you'll use your process's air flow rate, the wattage from above, the maximum air temperature, and the specification sheets of any heaters you're considering.

To understand the next step, it's important to know that temperature control for air process heating is achieved differently from most other industrial electric heating. Most heaters, like immersion, cartridge, and blanket heaters, are either on or off while they're functioning, and temperature control is achieved by turning them on or off at intervals. Air process heaters, however, are normally controlled more precisely, to allow them to adjust quickly to changes in air temperature. Rather than being simply on or off, air process heaters are usually on – but at a certain proportion of their maximum possible wattage. This proportion is regulated by the input voltage[1], which in turn is regulated by a PID temperature controller. An air process heater might never actually need to reach its maximum rated wattage.

The upshot of all this is that, instead of just (1) looking for a heater that can supply enough wattage, you're also (2) looking for a heater style that can withstand your process's maximum flow rate, as well as (3) its maximum temperature, and (4) specifying a heater that's physically sized so that it can produce the needed wattage without exceeding the maximum watt density for your flow rate.

For example

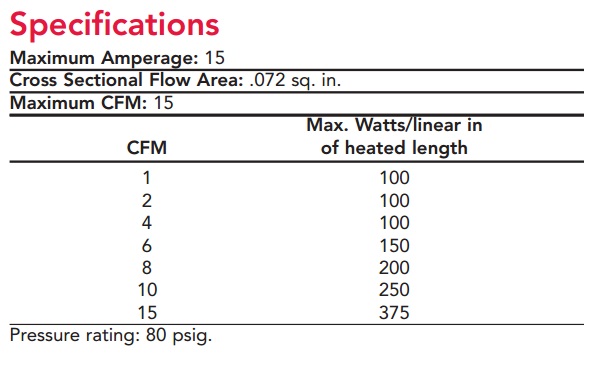

Let's take an example. Say you're heating air from 70°F to 200°F, at a flow rate of 10 SCFM; this calculates to 0.52 kW (that is, 520 W). All our standard circulation heater styles (Standard, Clean Air, Heavy Duty, and Maximum Flow) can perform at temperatures over 200°F. Looking at the specifications for standard air heaters, you find that the 3/8" size has a maximum flow rate of 8 CFM, but sizes from 1/2" up accommodate flow rates of 10 CFM. The standard sizes of 1/2" heaters, however, top out at 400 total watts of output, and you need 520 W. In the 5/8" heaters, you find several 5/8" × 6" models, each with a maximum wattage of 250 W per linear inch when the flow rate is 10 CFM (see right). Since your process, at 520 W, is well under 250 W/in, any of these models (depending on the voltage and pipe configuration you have available) will work in your process.

And there you have it. A few numbers, and a little bit of perusing the spec sheets, and you can find an air heater that works for your process.

If you're still not sure what air heater would be best for your process, we're happy to help. Give us a call at (866) 685-4443, email us at mailto:sales@oemheaters.com, or fill out one of our contact forms. We're here to help!

[1] Actually, effective voltage: the voltage itself isn't stepped down, but the power is cut off for a certain portion of each individual electrical wave (which is 1/60 sec long), so that the same voltage reaches the heater for a set fraction of the time. (Back to article)