866-685-4443 | Get in Touch Online ...

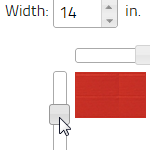

Silicone Rubber Heater Configurator

Configure your own built-to-order silicone rubber blanket heater, get an instant quote, and order online.

The etched element in these heaters provides superior heat transfer and exceptionally uniform heat output, which results in a faster warm-up cycle and longer life. The heaters operate in ambient temperatures from –80°F to 500°F.

Configuration of etched foil silicone rubber heaters, given the voltage, wattage, and resistance, is calculated using custom software. The lead time on custom etched foil silicone rubber heaters is usually 2–3 weeks. Note: Standard etched foil silicone heaters can be purchased here.

Advantages over wire-wound heating elements

- Higher watt densities

- Distributed wattages

- Elimination of edge loss compensation

- Greater element area over heater sheath

- Higher production quantities

- Complex heat distribution with a rating of about 200°C (392°F)

- Economical mass production

- Reproduction of complex circuits

Note: These etched foil heaters are built to order per application and require a quote. For a built-to-order heater quote (within one business day), please send us a contact form, e-mail us, or call us at (866) 685-4443.