866-685-4443 | Get in Touch Online ...

Cloth Heating Jacket Systems

Cloth heating jackets are flexible sheets of heated material that are configured to wrap closely around the item to be heated, and are fastened around the object to fully enclose it. Heating jackets maximize heat coverage and efficiency by providing both heat and insulation around the entire object. They are highly configurable and can be made to fit even the most unusual shapes. Because of this flexibility, they are ideal for a wide range of applications, which you can read more about below. Heating jackets are configured to order for each unique application. To get started configuring a jacket, just give us a call at (866) 685-4443, send us an e-mail at sales@oemheaters.com, or fill out one of our contact forms.

Highlights

- Heats all types of geometries (clamps and unistruts, valves, pipes, VCR nuts...).

- Suitable for a variety of environments, including cleanrooms.

- Achieves temperatures up to 1100°F.

- Exceptional heat uniformity and efficiency.

- Easy on-off installation with durable and reusable fasteners, excellent for tough-to-reach objects.

- Exceptional durability and product life, often 10 years or more.

- Economically reduces condensation buildup and contamination to increase productivity and reduce maintenance.

- Heats objects as small as ¼" diameter.

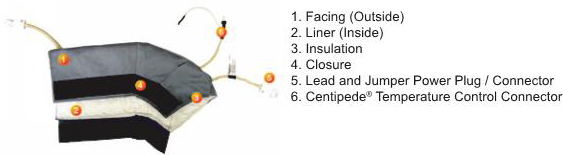

What are the parts to be specified on a cloth heating jacket?

- Liner and facing material: Liner is the layer between the object to be heated and insulation; facing is the outer shell of the jacket. Your environment determines the best liner and facing.

- Insulation thickness is as determined by application.

- Type of closure – for example, a hook-and-loop (Velcro®-like) closure.

- Power configuration: voltage, phase, frequency, lead and jumper power plug/connector.

If you have any questions regarding cloth heating jacket systems, please call us at (866) 685-4443, send us an e-mail at sales@oemheaters.com, or fill out a contact form.

Applications

- Heating gas or liquid lines, even in small diameters: for example, reducing gas condensation in BCl3, WF6, and other gas systems; viscosity control; and process heating.

- Gas abatement tool heating. Heating jackets are the only system that heats every pipe component: valves, bellows, elbows, clamps, etc.

- Tanks, drums, cylinders, and vessels

- Chemical vapor deposition (CVD)

- Emission testing

- Vacuum bake-out

- Exhaust lines

- High-energy physics, laboratory equipment

Specifications

- Patented grounded heating element

- Insulated for superior thermal efficiency and cool-to the-touch safety

- High temperature capabilities

- Up to 572°F (300°C) for Class 10 cleanrooms

- Up to 1100°F (593°C) for Class 100 cleanrooms

- Available for single- or three-phase wiring, 120 to 600VAC

- Built-in temperature sensors available

- Temperature control required